The concept of a circular economy is gaining traction as global awareness of environmental degradation and resource scarcity escalates. The traditional linear economy, characterized by a "take-make-dispose" model, is increasingly being scrutinized for its unsustainable practices. In contrast, the circular economy emphasizes resource efficiency, waste reduction, and sustainability. A pivotal mechanism in this shift is Extended Producer Responsibility (EPR), a policy framework that places the onus of waste management on producers.

The circular economy is an economic system aimed at minimizing waste and making the most of resources. It represents a significant shift from the conventional linear economy, focusing not just on profitability but also on social and environmental impacts. In a circular economy, products are designed for longevity, reuse, and recycling. This approach engages all stakeholders—from manufacturers to consumers—in responsible resource management.

Design for Longevity: Products are created with durability, repairability, and recyclability in mind, extending their lifecycle and ensuring they can be reused or repurposed.

Resource Recovery: Waste is viewed as a resource. Materials are recovered from used products and recycled back into the production process.

Systems Thinking: The circular economy adopts a holistic view of production and consumption systems, recognizing the interconnected nature of environmental, social, and economic factors.

Collaborative Consumption: Sharing, leasing, and resale models promote the use of products without ownership, extending their lifecycle and reducing waste.

The urgency for transitioning to a circular economy is underscored by several pressing global issues:

Resource Scarcity: With an increasing global population, the demand for natural resources is unsustainable. The depletion of raw materials necessitates a shift toward resource conservation.

Waste Management Crisis: Landfills are overflowing, and waste management systems are struggling to cope with the volume of waste generated. A circular economy aims to minimize waste generation and enhance recovery efforts.

Climate Change: The linear model contributes significantly to greenhouse gas emissions. A circular economy can mitigate climate impact through efficient resource use and reduced waste.

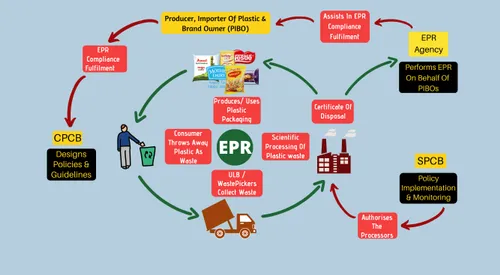

Extended Producer Responsibility (EPR) is an environmental policy approach that mandates producers to bear the responsibility for the entire lifecycle of their products, particularly regarding disposal and recycling. This includes the design, production, and end-of-life management of products. EPR aims to incentivize companies to reduce waste, improve product designs for sustainability, and engage in responsible waste management practices.

The concept of EPR emerged in the 1990s in Europe as countries sought ways to address increasing waste generation and promote recycling. Pioneering legislation was enacted in countries like Sweden and Germany, which set the stage for broader adoption. Over the years, the EPR model has evolved and spread to various sectors, including packaging, electronics, and textiles.

EPR can take different forms depending on the industry, regulations, and local contexts. The primary models include:

Individual Producer Responsibility: Producers are responsible for managing the waste generated by their products, including financing collection and recycling programs.

Collective Producer Responsibility: Producers collectively finance and operate a shared system for waste management. This model often involves industry associations that oversee compliance and implementation.

Mandatory Take-Back Systems: Producers are required to establish systems for returning products at the end of their lifecycle, facilitating proper recycling or disposal processes.

The packaging industry is one of the most affected by EPR regulations. With plastic waste posing significant environmental challenges, many countries have implemented EPR laws aimed at reducing packaging waste.

In 2021, France introduced the "Anti-Waste for a Circular Economy" law, which mandates that producers take responsibility for the entire lifecycle of their packaging. This regulation has prompted companies to innovate in their packaging designs, leading to reductions in plastic use, increased recyclability, and the adoption of alternative materials.

As a result of EPR regulations in packaging, companies are:

Investing in Sustainable Materials: Companies are prioritizing biodegradable and recyclable materials, focusing on designs that minimize waste.

Enhancing Recycling Programs: Many businesses are collaborating with municipalities and waste management companies to improve recycling infrastructure.

Communicating Transparently: EPR-induced accountability has driven companies to communicate more openly with consumers about their sustainability efforts, enhancing brand trust.

The electronics industry faces significant challenges related to e-waste, which contains hazardous materials that can harm the environment. EPR laws are being implemented in various countries to address these issues.

The EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandates that manufacturers are responsible for the collection, treatment, and recycling of e-waste. This legislation has led to major changes in how electronics companies design their products.

The electronics sector has responded to EPR with several initiatives:

Design for Disassembly: Manufacturers are designing products that can be easily disassembled for repair and recycling, reducing waste and promoting a circular approach.

Take-Back Programs: Many companies are implementing take-back schemes that allow consumers to return old devices for proper recycling.

Material Recovery: Companies are investing in technologies to recover valuable materials from e-waste, reducing dependency on virgin resources.

The fashion industry is notorious for its environmental impacts, with significant waste generated by fast fashion practices. EPR laws are emerging to change the landscape of textile production and consumption.

Sweden has introduced EPR regulations for textiles, requiring producers to finance the collection and recycling of used garments. This legislation represents a crucial step in addressing the growing issue of textile waste.

Textile producers are responding to EPR initiatives by:

Promoting Circular Fashion: Brands are increasingly focusing on circular fashion principles, including designing products for longevity and recyclability.

Collaborating on Initiatives: Companies are forming partnerships to develop solutions for textile recycling and waste management, enhancing overall industry sustainability.

Consumer Engagement: Producers are educating consumers on responsible garment disposal, encouraging recycling and reducing landfill contributions.

The automotive industry also faces challenges related to waste management, particularly concerning end-of-life vehicles. EPR laws address these challenges by holding manufacturers accountable for vehicle recycling.

Germany's Closed Substance Cycle Act mandates that automotive manufacturers ensure the recycling of vehicles once they reach the end of their lifecycle. This law has spurred innovative approaches for dismantling and repurposing automotive materials.

The automotive sector is adapting to EPR with solutions including:

Recycling Programs: Manufacturers are implementing programs for recovering valuable materials from old vehicles, including metals and plastics.

Sustainable Design: Companies are exploring sustainable design practices that enable easier recycling and reuse of vehicle components.

Extended Warranties: Offering warranties that encourage maintenance and repair helps extend the lifecycle of vehicles, reducing waste.

Waste Reduction: EPR encourages companies to minimize waste generation, facilitating a significant decrease in the amount of waste sent to landfills.

Increased Recycling Rates: By holding producers accountable for end-of-life products, EPR improves recycling rates and enhances resource recovery.

Conservation of Resources: EPR promotes the efficient use of resources and materials, lessening the demand for virgin materials and reducing environmental impacts associated with extraction and processing.

Innovation and Job Creation: The shift to circular practices fosters innovation in product design and waste management, leading to new business opportunities and job creation in recycling and recovery sectors.

Reduced Cleanup Costs: By incentivizing responsible waste management, EPR can help reduce costs associated with environmental cleanup and remediation.

Market Competitiveness: Companies that adopt EPR practices may gain a competitive edge by appealing to environmentally conscious consumers and accessing new sustainable markets.

Consumer Engagement: EPR encourages companies to communicate their sustainability efforts transparently, fostering trust and engagement with consumers.

Community Benefits: By investing in recycling infrastructure and programs, EPR can provide local communities with better waste management solutions and increased access to sustainable practices.

Enhanced Corporate Responsibility: EPR promotes a culture of responsibility among producers, aligning business objectives with societal and environmental goals.

Regulatory Complexity: EPR laws can involve complex regulations, making compliance challenging for businesses, particularly small and medium-sized enterprises (SMEs).

Data Collection and Reporting: Companies must be equipped to track and report data concerning waste management, which can be resource-intensive.

Cost Implications: Implementing EPR systems may impose additional costs on companies, potentially impacting their pricing strategies and competitiveness.

Market Distortions: There are concerns that EPR regulations may create market distortions, especially for smaller players unable to absorb compliance costs.

Awareness and Engagement: EPR's effectiveness relies on consumer participation in recycling programs. Low consumer awareness may undermine program success.

Convenience Factors: Consumers may be reluctant to engage in recycling and responsible product disposal if programs are not convenient or accessible.

As global awareness of environmental costs grows, it is likely that EPR regulations will expand across new sectors and regions. Governments may implement stricter policies to encourage greater corporate responsibility and sustainability.

Advancements in technology will play a crucial role in optimizing EPR systems. Innovations such as blockchain, artificial intelligence, and IoT sensors can streamline data collection, enhance tracking of products, and improve recycling processes.

Stakeholder engagement will be essential for EPR success. Collaboration among governments, businesses, and consumers will foster shared responsibility for resource management and waste reduction.

EPR can be integrated into broader sustainability policies, such as comprehensive waste management strategies and climate action plans. This integration can align goals and enhance the effectiveness of sustainability initiatives.

Extended Producer Responsibility (EPR) represents a transformative approach to managing waste and promoting a circular economy. By shifting accountability onto producers, EPR drives industries to innovate and adopt sustainable practices, reducing environmental impact and fostering resource conservation.

The rise of EPR laws across various sectors—including packaging, electronics, textiles, and automotive—illustrates a growing recognition of the urgent need for systemic change in resource management. While challenges remain, the benefits of EPR—such as increased recycling rates, enhanced corporate responsibility, and economic opportunities—highlight its potential for shaping a sustainable future.

As businesses, consumers, and governments work together to navigate the evolving landscape of EPR and promote circular economy principles, the path toward a more sustainable, resource-efficient world becomes increasingly attainable.